|

CMD-AS500 Intelligent Digital Inverter Arc Spray Machine

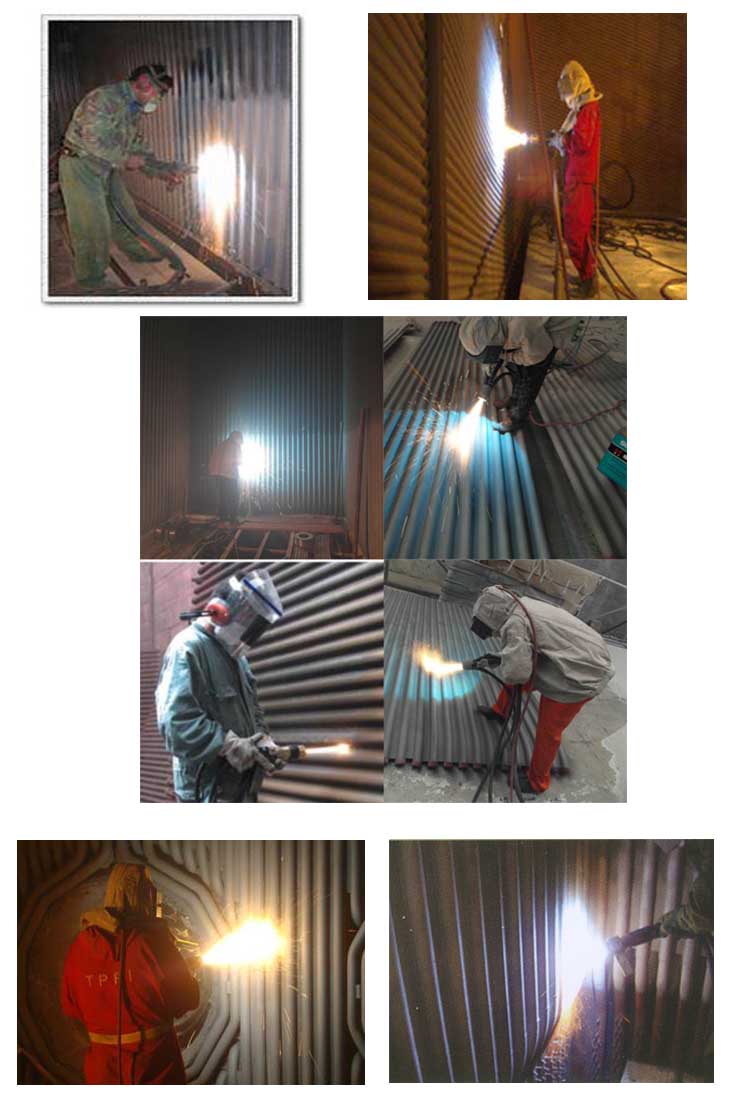

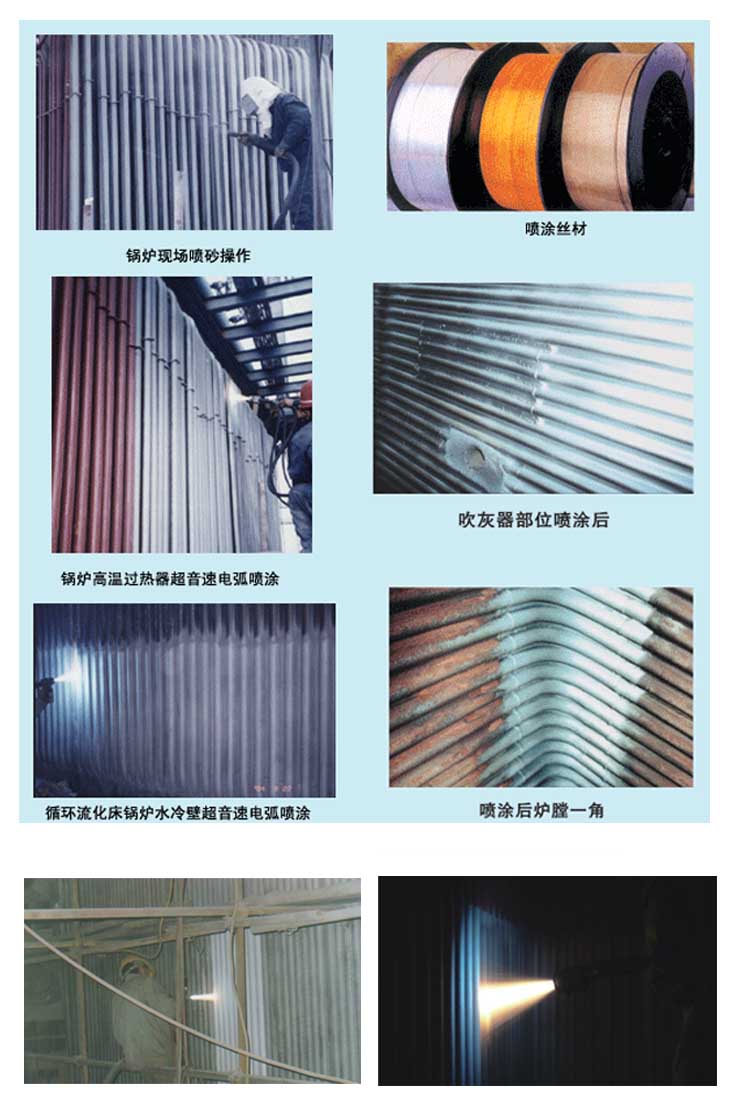

The principle of arc spray is using arc as hot source to atomize the melted metal wire, spray it to the surface of the work piece in high speed and then form a spray coating.

CMD-AS Intelligent Digital Inverter arc spray machine can spray Φ1.0

Technical characteristics | ||||

Model | AS300 | AS400 | AS500 | AS600 |

Power | 17 KVA | 24 KVA | 30 KVA | 35 KVA |

Input Voltage | AC380 V Three-phase | |||

Output Voltage | 10-45Vstepless adjustable | |||

Output Current | 20 | 50 | 50 | 50 |

Duty Cycle | 100% | |||

Wire Diameter | Φ1.0, Φ1.2, Φ1.5, Φ1.6, Φ2.0, Φ3.0 | |||

Deposition rate | ||||

Weight | ||||

Dimensions | 600×262×445(mm) | |||

Features |

1、Small size and light weight,easy to move on. Import IGBT tubes (fourth generation), high quality assurance. 2、Output voltage and current stable and smooth, strong anti-jamming capability. 3、Stable performance, reliable ignition, prevent to break arc, wire feeding smooth, reliable and can be 24 hours of continuous operation 4、The coating mass density is high, quality is good, porosity is less than 1%. 5、The coating combined with high strength: 30 Mpa - 50 Mpa 6、Arc spraying efficiency is high, stable arc, less spatter , coating deposition rate is 75% 95%。 7、flexible operation, arc spraying width can be fine-tuning. 8、High efficiency and energy saving, low consumption, power saving is 55% than ordinary arc machine . High power factor:up to 0.9. 9、A variety of options: wire drawing, wire pushing, wire drawing and pushing type, Spray inner wall of pipes φ>50. 10、 The whole machine modular, intelligent, digital display, high precision |

Drawing type arc spray gun

Inner Spray Gun | |

| CMD-EG20 |

Diameter | Φ |

Length | |

Standard Wire Tube Length | |

Optional Wire Tube Length | |

Wire Diameter | Φ |

Spraying productivity | |

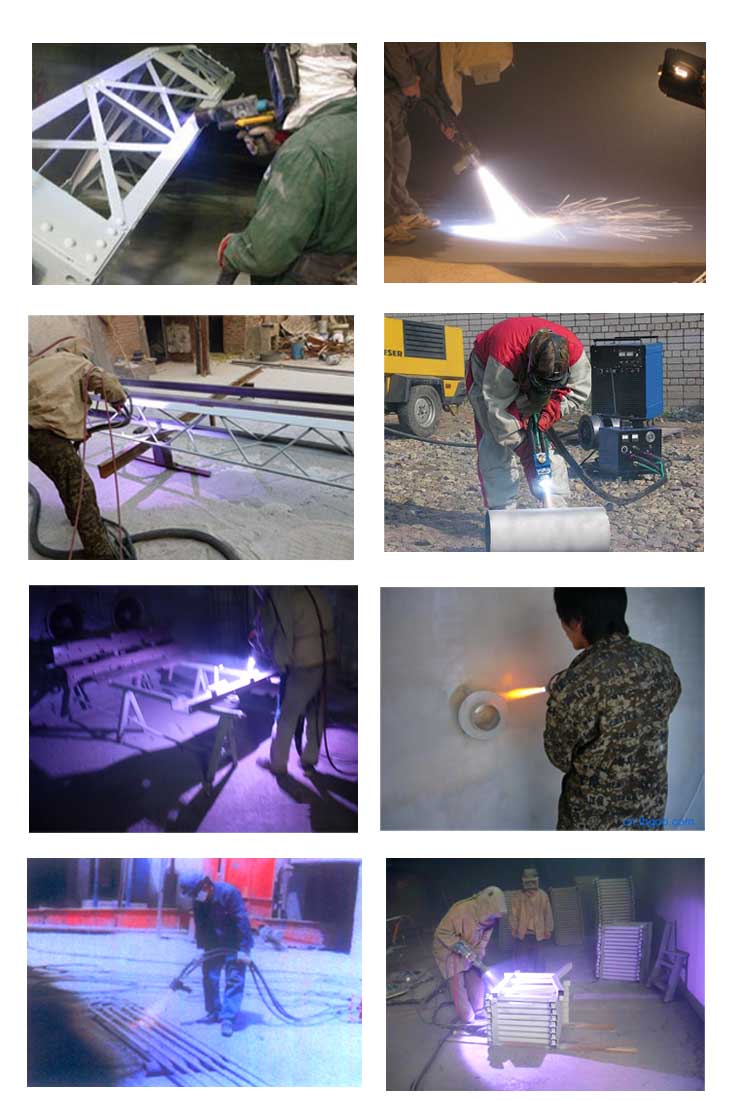

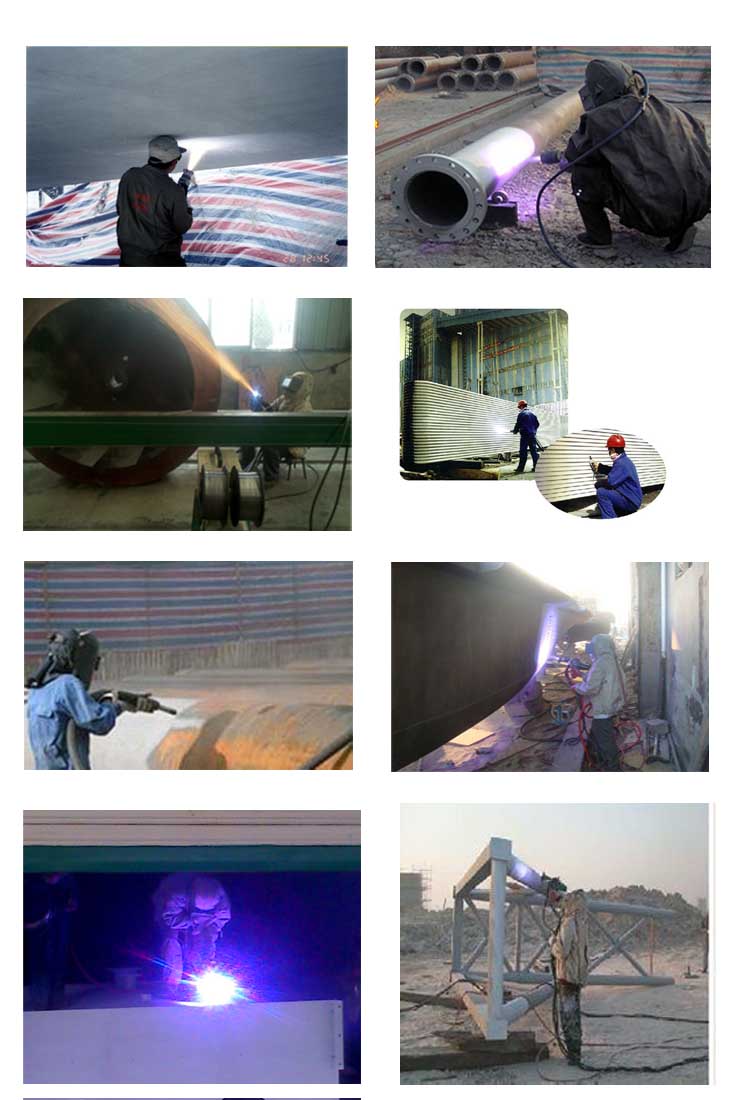

Application example of Arc Spray Machine

Spraying zinc, Instead of hot dip galvanized, Large area of anticorrosive coating

Spraying aluminum Replace the hot dip aluminum, Large area of anticorrosive coating.

Spraying Stainless Steel,Acid and alkali resistance

Spraying copper(Gypsum,resin,Glass fibre reinforced plastic)Decorative coating

Spraying Nickel and nickel alloy,3Cr13,7Cr13,Repair and Wear-resisting coating

Spraying nickel coating

Spraying Boron carbon composite wire,Repair fan blade,Pump impeller,Drawing disk,Slurry pipeline

Spraying Fe15Cr26WCTiCNi and Fe41WC/WC2

Spraying Nickel-chromium titanium,Fe-Cr-Al,High-chromium-nickel,Boron-carbon composite wire

Spraying High chromium boron wire,Repair paper machine dryer,(HRC55-70)

Spraying High-chromium-nickel coating,Repair Mine hydraulic support

- Arc sprayer (12)

- Plastic sprayer (2)

- Ceramic sprayer (3)

- Plasma sprayer (1)

- Blast sprayer (1)

- Spray material (1)

- Thermal spray gun (1)

- Airless Sprayer (13)

- JS Waterproof Sprayer (5)

- Recycling sandblaster (5)

- Open Sandblaster (0)

- Box Sandblaser (0)

- Inner wall gun (4)