search the product

|

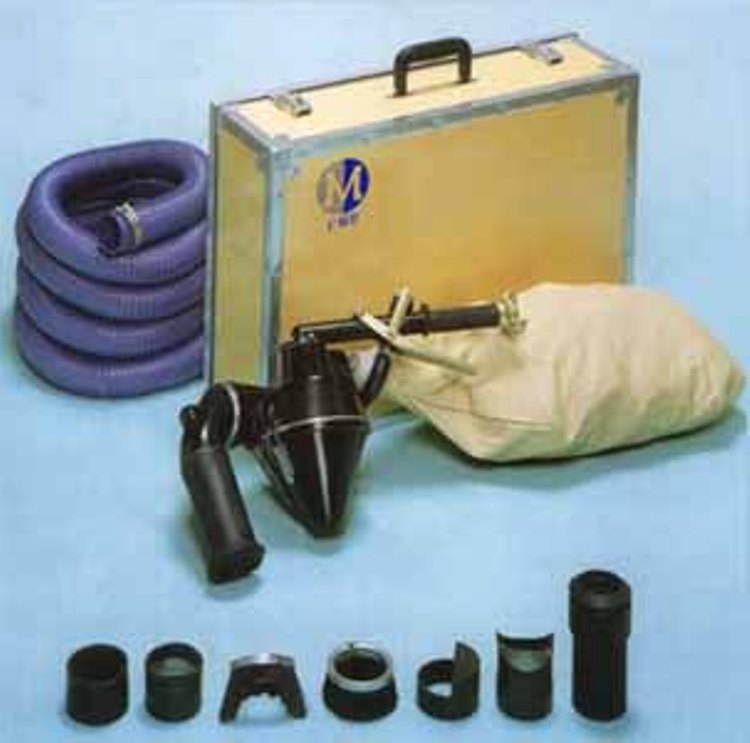

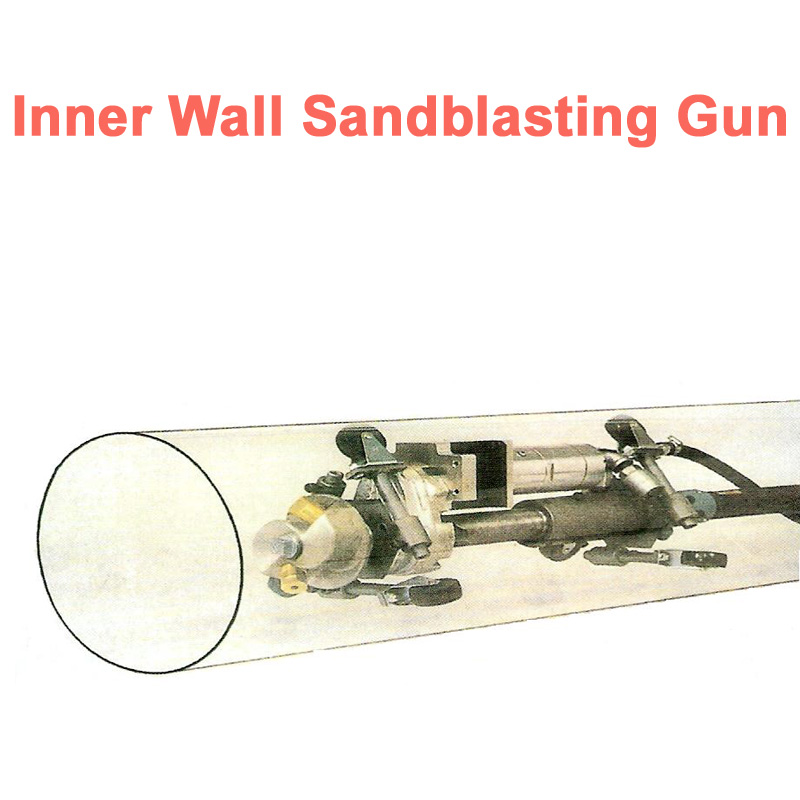

EB50 Inner wall sandblasting gun Sandblasting the inner wall of the pipe

Connect the CMD-EB pipe inner wall sandblasting (pellet) gun to any CMD series sandblasting (pellet) machine to work 360° automatic sandblasting (pellet) work.

CMD-EB50 Inner wall sandblasting gun Sandblasting the inner wall of the pipe

CMD pressure feeding open type sandblasting (pellet) machine has fixed type, movable type, manual control, pneumatic control, electric control, single warehouse, double warehouse, single gun, double gun, sand blasting gun for the inner wall of the pipeline, etc., but no matter which A sandblasting (pellet) machine has the same purpose, which are:

1. Derusting and removing oxide skin before painting or thermal spraying of large steel structures, bridges, hulls, oil tanks, chemical storage tanks, light poles, iron towers, containers, etc.

2. For various castings, forgings, etc., it can not only remove molding sand, oxide scale, residues, burrs, etc. on the surface of castings and forgings, but also play a polishing role and improve the surface finish of castings and forgings.

3. The use of plastic sand or resin sand can remove the old paint on the surfaces that need to be repainted every year, such as ship hulls, airplanes, large locomotives, etc.

4. Shot peening: For large integral panels, shot peening can be used, which is both beautiful and economical.

5. Shot peening: Under the condition that the geometric shape of the workpiece remains unchanged, the workpiece can be strengthened with shot peening to increase the residual compressive stress on the surface of the workpiece and eliminate the residual tensile stress, thereby significantly improving the fatigue resistance of the workpiece. Stress and corrosion resistance.

6. Shot peening correction: There are a lot of deformation problems in the workpiece during processing and use. Some deformations can be corrected by conventional methods, but for those elastic deformations with a small deformation amount of 0.1-0.3 mm, the shot peening correction technology can be used to solve the problems in conventional production. There are many deformation technical problems.

7. Mold surface treatment: Generally, sandblasting can be used to treat the surface of molds, such as: wire cutting molds, glass molds, tire molds, conductive rubber molds, shoe molds, bakelite molds, electroplating molds, button molds, plastic molds And the treatment of the matte surface after the mold bites the flower.

8. Processing of large-scale glass and marble: sandblasting can be used to process the surface of large-scale glass and marble.

CMD pressure feeding open type sandblasting (pellet) machine has fixed type, movable type, manual control, pneumatic control, electric control, single warehouse, double warehouse, single gun, double gun, sand blasting gun for the inner wall of the pipeline, etc., but no matter which A sandblasting (pellet) machine has the same purpose, which are:

1. Derusting and removing oxide skin before painting or thermal spraying of large steel structures, bridges, hulls, oil tanks, chemical storage tanks, light poles, iron towers, containers, etc.

2. For various castings, forgings, etc., it can not only remove molding sand, oxide scale, residues, burrs, etc. on the surface of castings and forgings, but also play a polishing role and improve the surface finish of castings and forgings.

3. The use of plastic sand or resin sand can remove the old paint on the surfaces that need to be repainted every year, such as ship hulls, airplanes, large locomotives, etc.

4. Shot peening: For large integral panels, shot peening can be used, which is both beautiful and economical.

5. Shot peening: Under the condition that the geometric shape of the workpiece remains unchanged, the workpiece can be strengthened with shot peening to increase the residual compressive stress on the surface of the workpiece and eliminate the residual tensile stress, thereby significantly improving the fatigue resistance of the workpiece. Stress and corrosion resistance.

6. Shot peening correction: There are a lot of deformation problems in the workpiece during processing and use. Some deformations can be corrected by conventional methods, but for those elastic deformations with a small deformation amount of 0.1-0.3 mm, the shot peening correction technology can be used to solve the problems in conventional production. There are many deformation technical problems.

7. Mold surface treatment: Generally, sandblasting can be used to treat the surface of molds, such as: wire cutting molds, glass molds, tire molds, conductive rubber molds, shoe molds, bakelite molds, electroplating molds, button molds, plastic molds And the treatment of the matte surface after the mold bites the flower.

8. Processing of large-scale glass and marble: sandblasting can be used to process the surface of large-scale glass and marble.

CMD Inner wall sandblasting gun technical parameters | ||||

model | CMD-EB50 | CMD-EB100 | CMD-EB300 | CMD-EB900 |

Pipe inner diameter | Φ33-50mm | Φ33-100mm | Φ50 | Φ200 |

Pipe length | ||||

Features of CMD Inner Wall Sandblasting Gun | ||||

Connect the CMD-EB pipe inner wall sandblasting (pellet) gun to any CMD series sandblasting (pellet) machine to work 360° automatic sandblasting (pellet) work. | ||||

product category

Thermal sprayer (21)

- Arc sprayer (12)

- Plastic sprayer (2)

- Ceramic sprayer (3)

- Plasma sprayer (1)

- Blast sprayer (1)

- Spray material (1)

- Thermal spray gun (1)

Washing Machine (17)

Coating Machine (18)

- Airless Sprayer (13)

- JS Waterproof Sprayer (5)

- Recycling sandblaster (5)

- Open Sandblaster (0)

- Box Sandblaser (0)

- Inner wall gun (4)

清洗设备 (23)

热喷涂设备 (18)

喷砂设备 (4)

涂装设备 (14)